Corrective system maintenance

This type of maintenance consist on performing a series of technical revisions to the equipment according to their system requirements, like their temperature adjustment capacity and their ability to maintain adecuate humidity levels.

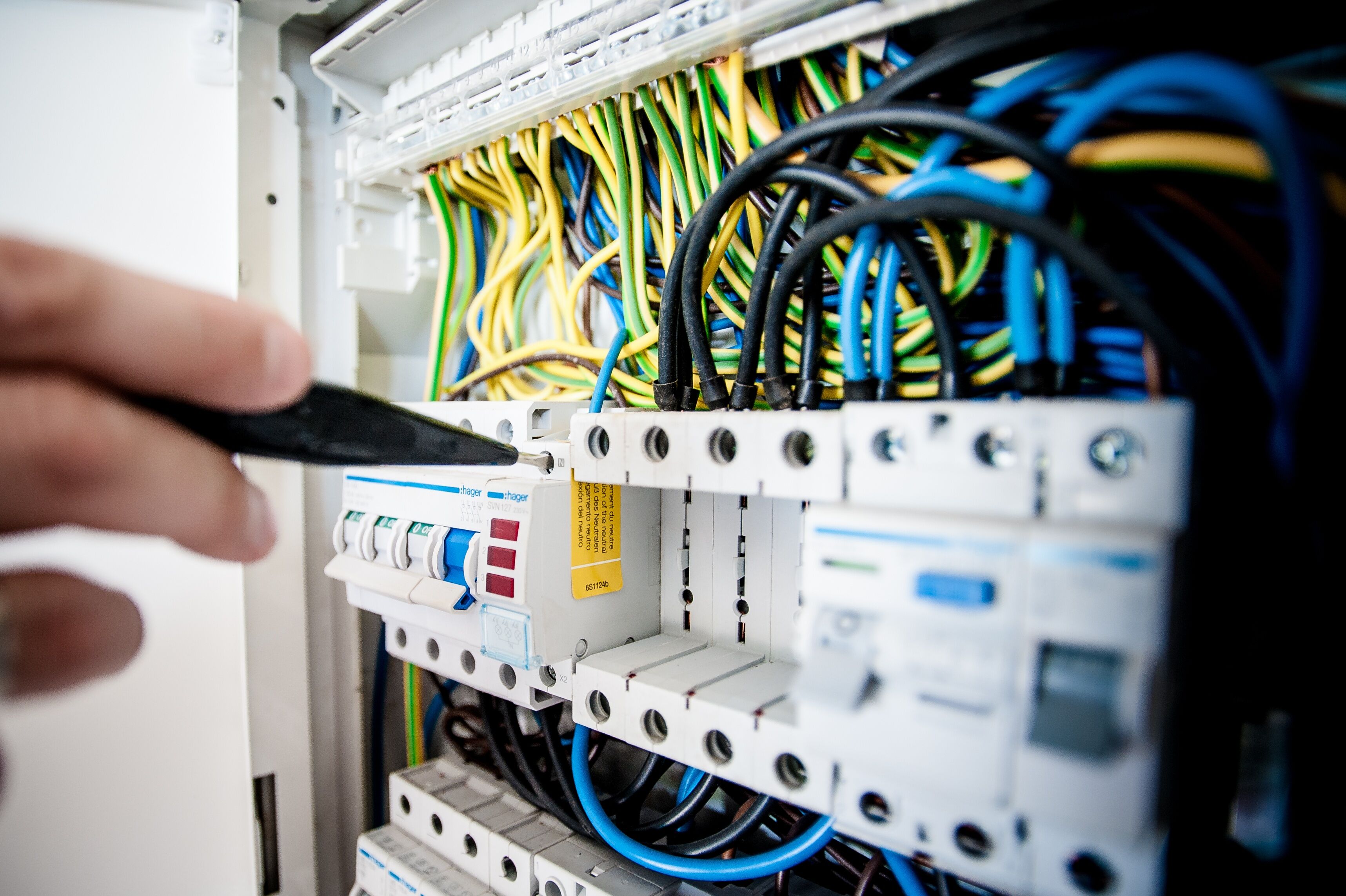

During testing, posible fail causes are identified, such as mechanical damages (for examplem, in ventilation pieces), electric problems (like basly installed cables unadjusted systems), or liquid/gas leak (such as cooling liquid). Once the necessary repairs are complete, the system is checked for it's proper performance, ensuring optimal operational behaviour.

Preventive system maintenance

In this maintenance, the machine's current performance is reviewed and a detailed inspection about the individual sections of the system is worked on.

Cleaning procedures are given to filters, air conducts, evaporator and condensator coils, as well as other specific pieces of each system. Seals and posible leaks are verified, electric component are inspected, and mechanical pieces of high use are checked, identifying posible damages, dealt by either internal or external factors, such as moss or hits.

Electric, pneumatic, and hidraulic instalations

Depending on the instalation type, electric conexions are built with cables, plugs and switched. Machinery and valves are installed, ensuring a functioning air compression, and pipes and pumping equipment is prepared for ideal hidraulic performance.

Also, specifics of complex machinery can be managed for this kind of instalations.

Electric control design

Diagrams are made and a plan is developed for the necessary sensors inside the system, making sure the machinery regulates the operation according to the responses acquired by its components.

During testing, key thermodynamic variables, such as temperature, pressure, and humidity, are verified to be within optimal levels. This process is aplied to systems such as temperature chambers, humidifiers, and cooling rooms.

Updating controlers

Elements of the system that require improvements or updating are replaced, changing good amount of wiring and sensors, implementing a reworked design of the machinery that improves over the last presented effectiveness.

Selling and replacement of cooling system's parts

Attending to our client's needs, we provide the necessary pieces to complete the previously mentioned services to the machinery, which optimizes working times and ensures high efficiency.

Thanks to our storage facilities with spare inventory, we can offer this service even in areas outside our local community.